One of the coolest organizations I've had the chance to work with is E-nabling the Future. They work with engineers, designers, and 3d-printing hobbiests to provide low-cost prosthetic arms for anyone who needs them.

At the Rehabiliation and Neuromuscular (ReNeu) Robotics Lab, I met Maddie, who had a recent amputation and was interested in 3d-printing a temporary replacement. In just 2 weeks, a labmate and I customized, printed, and assembled an E-Nable design that Maddie could use to help with daily activities. Now she has a state-of-the-art robotic hand, but the 3d-printed version helped for 4 months or so before she could get that.

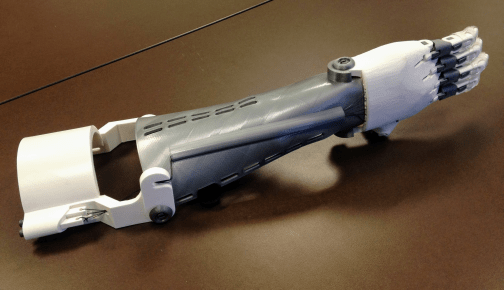

There are elastic bands around each knuckle that keep the fingers open at a resting position. When the elbow is flexed, however, cables pull the fingers closed into a grasping pose.

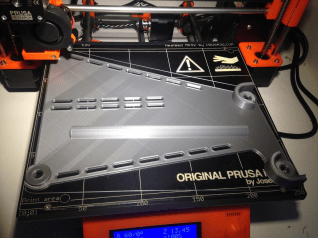

Many of the parts in this arm were printed flat and then thermoformed into a shape that matches the contour of a forearm. This increased print quality, strength, and comfort.

Special thanks to my labmate Taylor for helping me! This project ended up catching some media attention - here's an article written in the engineering magazine.